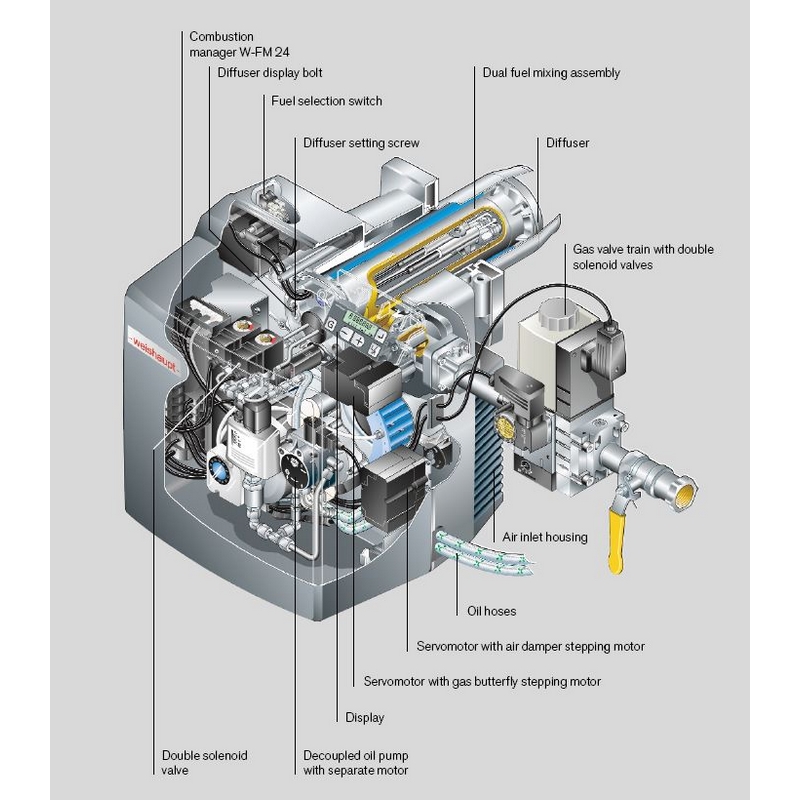

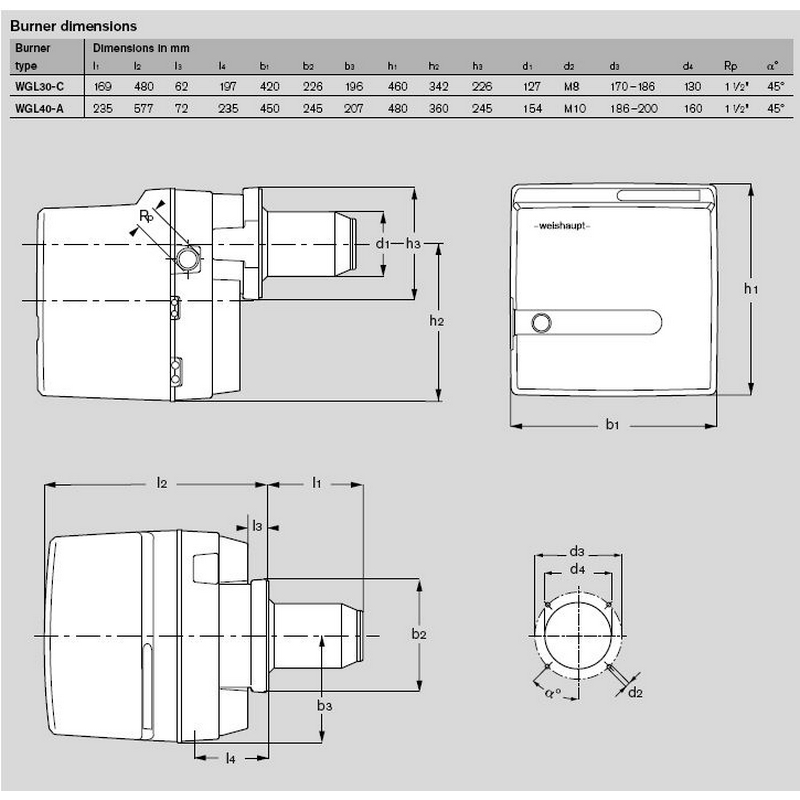

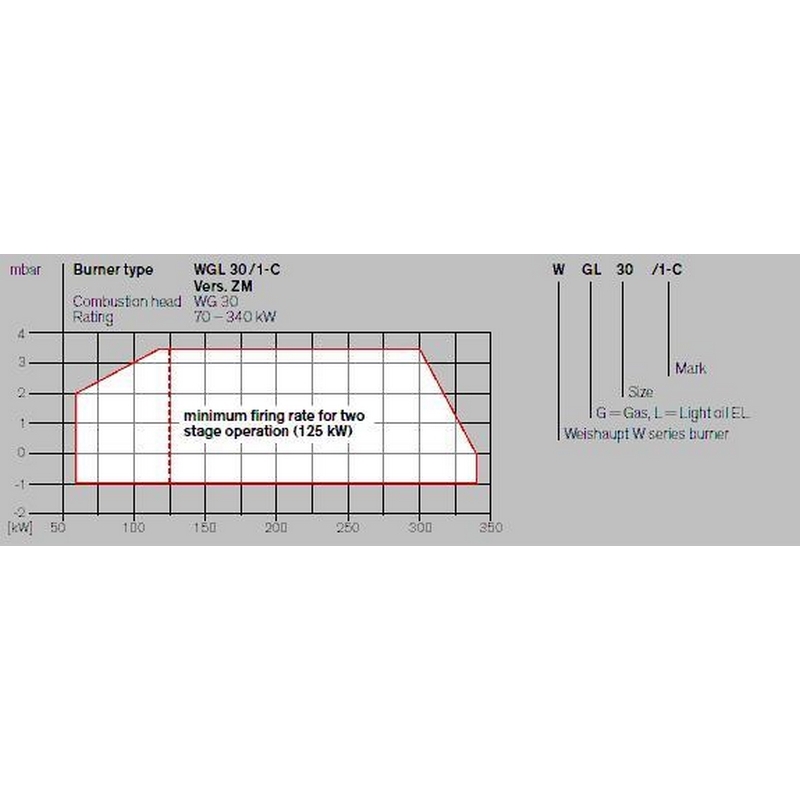

Dual-fuel Burners WGL30 and WGL40 -weishaupt-

Weishaupt dual-fuel burners can operate on gas or oil, with gas usually being the primary fuel. Fuel change-over can take place while the burner is operating. Fuel change-over can also be effected remotely by a master control system - important for applications where a continual supply of heat is essential, for example in botanical nurseries.

Outstanding efficiency:

Digital combustion management ensures that only the precise amount of fuel that is needed at that precise moment is used. The oil pump is driven by a separate motor and is disconnected when the burner is firing on gas, thus preserving the pump and saving electrical energy. The electronically controlled air damper closes fully on shutdown to hinder cooling of the combustion chamber.

Exemplary emissions:

Weishaupt Low-NO? technology (standard on gas burners, optional for oil burners) utilises a special mixing assembly to effect a notable reduction in harmful emissions.

Quiet operation:

The burner’s transverse-mounted fan is sound attenuated.

Long service life:

There are many years of experience and development behind Weishaupt’s burner technology. Only the best quality materials are used in manufacture.

Cost-effective price/capacity ratio:

The advanced mixing assembly reduces the burner’s required minimum gas supply pressure, so a smaller gas valve train can be used.

Reciprocal monitoring:

Two microprocessors monitor each other, ensuring a high degree of safety.

Future-proof:

Digital combustion management enables communication with other systems, thanks to the integrated eBUS connection. This makes remote burner monitoring, setting, and diagnosis possible, as well as facilitating the integration of the burner with a building management system

A safe investment in the future

Reliable and economical:

The millionfold success of the Weishaupt compact burners is the result of orienting without compromise towards quality and the customer. The technology has been constantly developed and improved over decades. The latest production methods and stringent quality checks of all products ensure Weishaupt’s reputation for quality. You are making a safe investment in the future. The WGL integrates seamlessly with the other burners in the W series family to unite all the advantages of the W series with increased fuel flexibility.

Large capacity range

The large capacity range of 70 to 340 kW and 125 to 550 kW makes the burners suitable for the widest range of heat exchangers.

Electronic ignition

The W-ZG 01 ignition unit used on all Weishaupt W burners is particularly energy efficient and extremely reliable. Valve proving as standard with the W-FM24 combustion manager The low gas pressure switch is used to check the tightness of the gas valves, thus providing valve proving without the need for any additional components or costs.

Gas multifunction assembly

The Weishaupt gas multifunction assembly incorporates the following components/functions:

- Servo-controlled gas pressure governor for continual gas pressure

- 2 solenoid valves (Class A)

- Filter

- Gas pressure switch If the gas pressure falls too low, a low gas pressure program is started. The gas pressure switch also provides for automatic valve proving.

All burners are tested by an independent body and conform to the following standards and EU directives:

- EN 267

- Gas Appliance Directive 90/396/EEC

- EN 676

- Machinery Directive 98/37/EC

- Electromagnetic Compatability Directive 9/336/EEC

- Low Voltage Directive 73/23/EEC

- Boiler Efficiency Directive 92/42/EEC

- Pressure Equipment Directive 97/23/EC