What is the D.S.A. system?

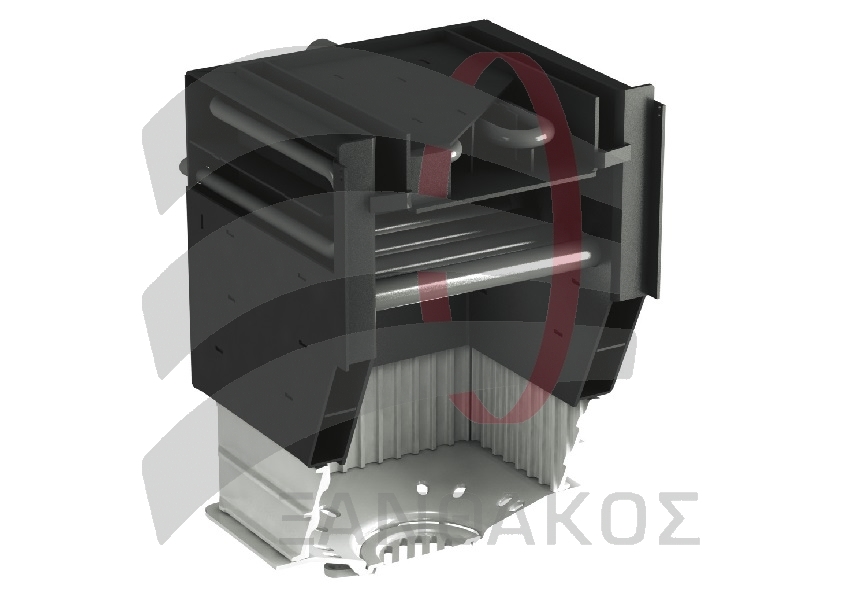

The D.S.A. system is a La Nordica - Extraflame innovation, which enables us to connect safely, a wood burning boiler to a closed expansion tank heating installation. It is a fully automatic safety device which reduces the water temperature rapidly in the boiler, in compliance with current regulations and standards. It consists of a heat discharge coil integrated in the boiler and a temperature actuated valve connected to the water supply.

How it works?

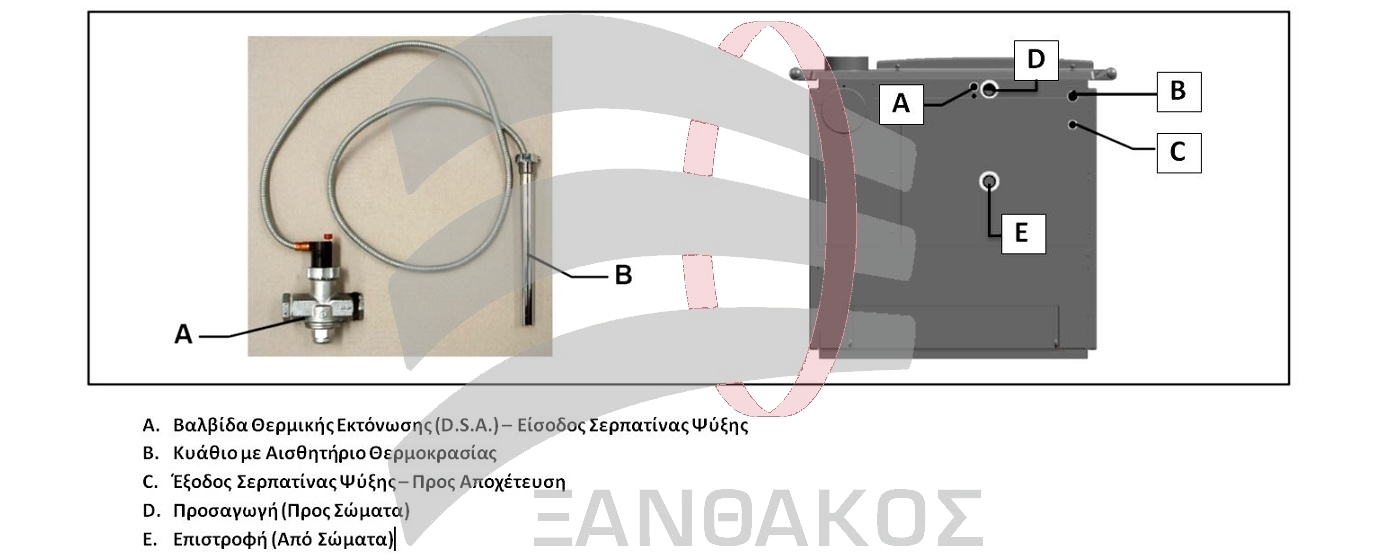

The D.S.A. valve is an automatic thermo-mechanical valve which is normally closed. When the water temperature into the boiler rises over a preset safety temperature, (usually 95?C), the D.S.A. valve opens, enabling cold (tap) water to run through the heat discharge coil, thus reducing the boiler’s water temperature.

Hydraulic connections:

The D.S.A. valve has 2 water connections. The entering side must be connected to tap water, and the other to the heat discharge coil (integrated to the boiler). Be sure to follow the flow direction arrow! The exiting side of the heat discharge coil, must be properly connected to drainage network. The cooling system pressure must be at least 1,5bar.

For safety reasons, It is COMPULSORY that a CLOSED expansion Tank system is provided AT LEAST with:

1. A 3 bar SAFETY VALVE - VSP: maximum operation pressure allowed for the system is 3 bar (equal to 30 m of the water column). Higher pressures can cause deformation and breakage of the boiler body.

2. AUTOMATIC THERMOSTATIC MIXING VALVE 55°C: it prevents cold water return in the exchanger. While the temperature of water is lower than 55°C, the valve along with the pump installed on the return, guarantee water re-circulation inside the biomass boiler exchanger. The elevated return temperature, allows efficiency improvement, reduces formation of smoke condensation and prolongs the boiler life span. Valves on the market have different calibrations. La NORDICA advises the use of model 55°C with 1” hydraulic connections. Once the valve calibration temperature is reached, valve gradually opens and the boiler water goes to the system. IMPORTANT: lack of installation of the device voids the heat exchanger warranty.

3. HEAT DISCHARGE VALVE or TEMPERATURE SAFETY RELIEF VALVE 95°C - VST, with double safety sensor

4. CLOSED EXPANSION Tank can be installed on the thermo product return pipe.

6. NOISE ALARM ACTIVATION THERMOSTAT

7. NOISE ALARM

8. TEMPERATURE INDICATOR

9. PRESSURE INDICATOR

10. PUMP SYSTEM